Cone Crusher

Production Capacity:12-1000t/h

Discharge opening: 3-60mm

Feeding size: 35-300mm

Applied material: barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum.

Production Capacity:12-1000t/h

Discharge opening: 3-60mm

Feeding size: 35-300mm

Applied material: barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum.

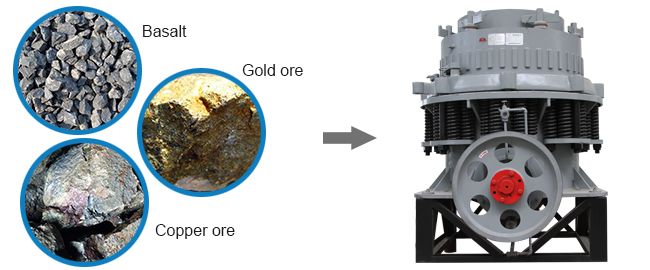

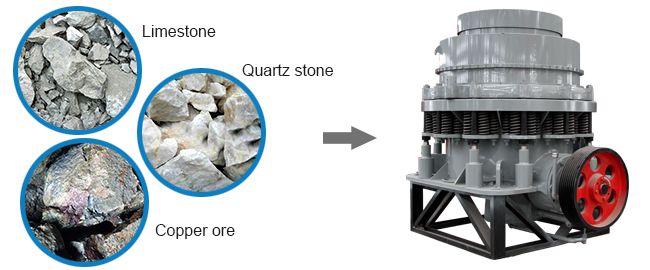

The china cone crusher can be used as a kind of gyratory cone crusher for crushing ores and rocks with medium hardness and above in metallurgy, construction, road building, chemistry and silicate industry. Our hydraulic cone crusher has the advantages of big crushing ratio, high efficiency, low energy consumption and uniform particle size, and the gyratory china cone crusher is suitable for the medium crushing and fine crushing of all kinds of ores and rocks.

When the cone crusher is running, the motor is rotating driven by pulley or coupling, drive shaft and the conus in the eccentric sleeve, under which the motor of the cone crusher is forced to move around the fixed rotary pendulum, thus the crushing wall near the rolled Shirakabe surface can be mounted on the the adjustment sleeve.

When foreign materials are sent into crushing cavity,the cone crusher will start the spring insurance system for safety, and the discharging mouth will be larger, so the foreign matter will be discharged from the crushing chamber. We can use cleaning chamber system if foreign materials are stuck.

Based on the hydraulic system, the hydraulic cone crusher can be classified into multi-cylinder hydraulic cone crusher (HPC series) and single cylinder hydraulic cone crusher (HCS Series)

.jpg)

.jpg)

.jpg)

HPC series hydraulic cone crusher is a type of world advanced and high efficient cone crusher, and realizes the perfect combination of breaking speed, eccentricity (stroke) and high-performance crushing chamber design, which can not only improve the production capacity and crushing efficiency, but also expand the application scope. The crushing range of the gyratory cone crusher from limestone to basalt, from stone production to crushing all kinds of ore materials is able to provide unparalleled fragmentation performance in medium crushing, fine crushing and the ultra-fine crushing operation. The high rotating speed, large crushing capacity and unique patented design make the finished products have high quality and cube type. In addition, easy maintenance ensures exceptional stability on operation, so it is renowned throughout the world. HPC Cone Crusher is the latest product can replace spring cone crusher and general hydraulic cone crusher.

HCS high-performance cone crusher is used for crushing various minerals and rocks with medium hardness or above. The machine has features of big crushing force, high efficiency, large handling capacity, low-cost operation, easy to adjust and cheap price. Because of the reasonable components and structural design, HCS cone crusher has long service life, uniform product particle size, less cycling load, etc. Each specification of HCS Cone Crusher has a lot of crusher cavities, so users can select different type of chamber according to different needs to better meet the needs.

| Specification | Model | Diameter of large end of crushing cone (mm) |

Max.feeding size(mm) |

Width of discharge opening (mm) |

Processing capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

| Specification | Max.feeding size(mm) |

Processing capacity (t/h) |

| Φ600 | 65 | 40 |

| 35 | 12-23 | |

| Φ900 | 115 | 50-90 |

| 60 | 20-65 | |

| 50 | 15-50 | |

| Φ1200 | 145 | 110-168 |

| 100 | 42-135 | |

| 50 | 18-105 | |

| Φ1750 | 215 | 180-360 |

| 185 | 80-210 | |

| 85 | 60-180 | |

| Φ2200 | 300 | 420-700 |

| 230 | 130-410 | |

| 100 | 80-200 |